Specification

We are one of the reputed plate heat exchanger and maintenance requirements. With an esteemed and proven brand, we supply our products blended with high quality and competitive pricing as well to benefit our customers. Being an authorised stockist for Plate Heat Exchanger; Gaskets, Plates, Rubber Spools and others Spares from all major makes and models. We also provide cleaning chemicals that serves all our client needs for most of the cleaning intents. The cleaning chemicals that we manufacture are backed up with experience and certification of competent chemists to ensure that they are of the highest quality. We also supply a complete and distinct line of power transmission belts for both automotive and industrial applications

OUR SPECIALIST SERVICES COMPRISES OF:

High Pressure Washing

Chemical Cleaning Operation

Dye Penetrant Test

Re-gasket

Oven-Curing

This apart we undertake Supply of Gaskets, Plates and Plate Heat Exchangers

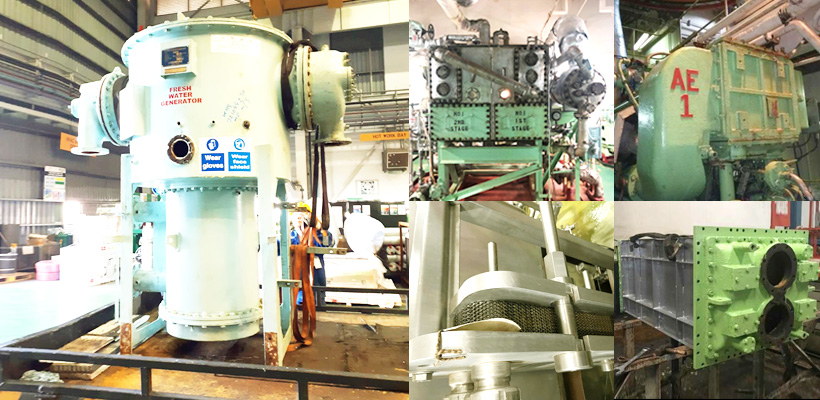

Our Works

PLATE HEAT EXCHANGERS

We are a dedicated and specialised service repair and maintenance program specialists, with a familiarity in the marine, oil & gas industry sectors. Backed up with an optimal level of expertise to handle all types of plate heat exchanger jobs from a full servicing, major or minor repairs and troubleshooting, to the most basic maintenance programs to ensure optimal efficiency in running your plate heat exchangers to maximize machinery output we render unmatched services to our esteemed clientele..

Removal and overhauling of plate heat exchangers

Our carefully crafted servicing programs set off with a detailed and carefully executed removal and refitting plan to meet the most stringent schedules. Our highly experienced team of veteran service engineers and removal specialists will ensure that we remove or refit in a safe and expedient manner so as to ensure that we do not hold up any other vital functions within the engine room or plants, at the shipyard, in anchorage, or your building or plant – service excellence is always our first priority..

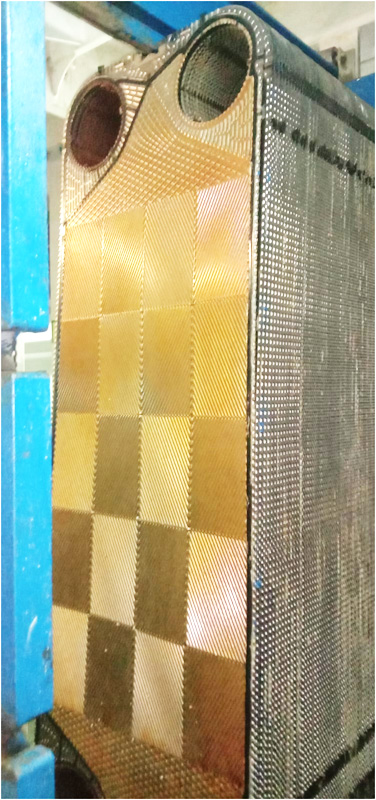

Cleaning

All gaskets are meticulously removed to preserve their material compounds to extend the lives where necessary. The plates are pre-washed, then de-greased and/or de-scaled through a careful process mapped out by our operations and service engineer to ensure that no contaminants are left on the plate. After which the plates are put through a system of high-pressure washing to ensure a clean and clear surface

Checking

The plates are then checked to ensure that the plates are in optimal working condition through a system of dye-penetrant test and ultra violet tests to check for cracks, pin-holes, material failure, or possible degradation due to years of wear and tear.

Re-Gasketting

The plates are then carefully re-gasketted with high quality or genuine gaskets using our special adhesives and cured to ensure proper bonding between the gaskets and the plates

Gasket Supply

We stock gaskets for the most common models of Plate Heat Exchanger brands such as Alfa Laval, APV, Tranter, SWEP, GEA etc in our climate controlled store to ensure maximum viability of our gasket stocks to deliver the best results.

Plate Supply

We also supply reconditioned and new plates for Alfa Laval, APV, Tranter, SWEP, GEA, and other popular brands of Plate Heat Exchangers. Our global network of affiliates will ensure that we can source and deliver your plates to you to minimize your down-time should you be faced with plate failure.

Specialist Services

Our team of dedicated service engineers and specialists will travel to any part of the World to offer our specialist services such as troubleshooting and problem solving for vessels anywhere around the globe to deliver our service excellence where ever we can be of service to the client.

Our Works

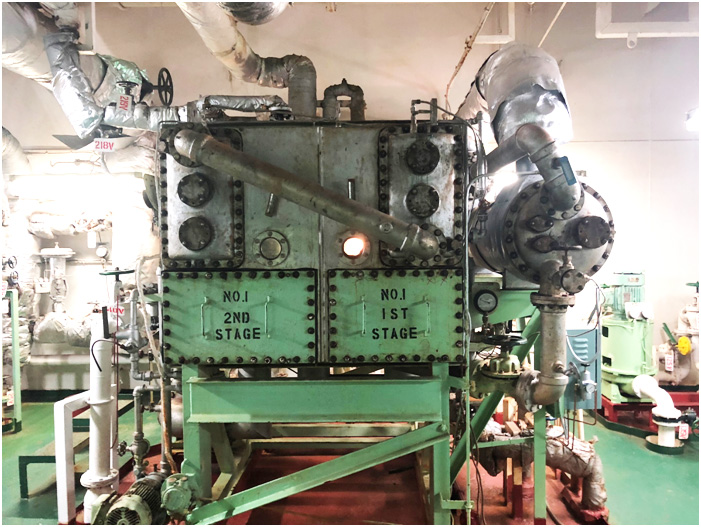

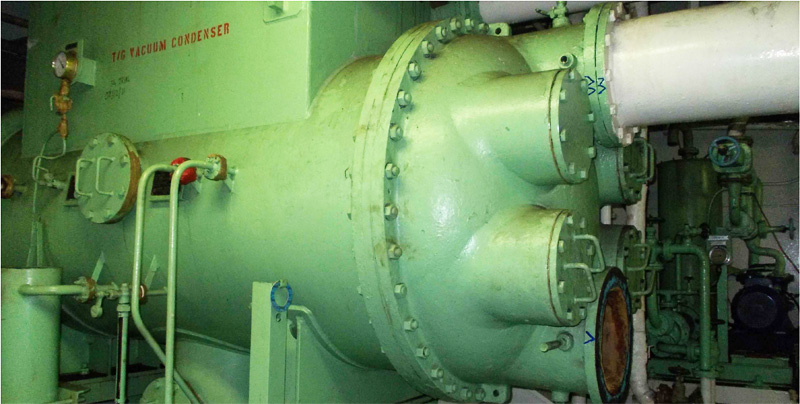

SHELL & TUBE EXCHANGERS

We offer cleaning, servicing, re-tubing, & complete fabrication. Providing a package of expertise to enable clients to entrust us with their requirements from re-tubing to a complete full fabrication. We possess the technological and know-how from using state of the art modelling and design, complex Heat transfer calculations, to our experienced team professionally ensures that the job is always done right to fulfil the client requirements and timelines in an efficient manner.

Removal and Refitting of Shell & Tube Heat Exchangers

Our services begin with a detailed and carefully executed removal and refitting plan to meet the most stringent schedules. Our highly experienced veteran team of service engineers and removal specialists will ensure that the removal or refit is carried out in a safe, and expedient manner at the shipyard, whether in the anchorage or the building or in the plant.

Cleaning

Cleaning of the Shell & Tube Heat Exchanger is done in a system of chemical cleaning which involves de-greasing, de-scaling, Neutralizing, ultra-sonic cleaning, and high pressure washing to ensure that the tube bundle is clean of all chokes and impurities. The tubes are also subject to a cleaning regime to ensure that the tubes are cleared of all chokes and blockages.

Re-Tubing and Repair of Shell & Tube Heat Exchangers

Our specialists conduct re-tubing of the shell & tube heat exchanger using the latest state of the art tooling in our workshops, at the shipyard, or on-board your vessels at the client’s convenience to ensure that we can provide our very best to keep the critical operations running smoothly with as little interruptions as possible.

Complete Fabrication and Re-engineering

Our skilled designers and engineers will re-design or fabricate shell & tube heat exchangers to the demands and configurations precisely to ensure optimal heat transfer and efficiency that meets up to the demands using the latest software, tools and machinery.

Specialist Services

Our team of dedicated service engineers and specialists will travel to any part of the World to troubleshoot, re-tube, remove chokes in Shell & Tube Heat Exchangers for vessels anywhere around the globe to your convenience and satisfaction.

Our Works

Main engine charge air coolers

The Main Engine Charge Air Coolers are the heart and soul of an engine. Ensuring optimal running efficiency and engine performance apparently helps ship owners and ship managers save on fuel and maintain timeliness and schedules accurately. Our team of engineers and service specialists deliver a suite of services from cleaning to manufacturing charged air coolers to meet the client expectations and the optimal engine needs as well.

Cleaning

The cleaning of the main engine charged air cooler is done by chemical cleaning which involves de-greasing, de-scaling, neutralizing, ultra-sonic cleaning, and high pressure washing to ensure that the unit is clean of all chokes and impurities. Then the pertaining tubes are subjected to a cleaning regime to ensure that these tubes are also cleared of all chokes and blockages. A detailed testing regime, including hydrostatic testing and air testing is carried out to ensure that the main engine charged air cooler is operating at its maximum potential. All servicing procedures are done according to stringent ISO 9001-2008 standards to ensure that a top rated service is delivered to the client.

Fabrication, Re-Engineering, and Design of Air Coolers

Our professional team of experienced designers and engineers design, re-engineer and fabricate charged air cooler to the exact needs and specifications using the best materials to achieve product excellence and maximum output and optimal performance each and every time. Using the latest design and engineering software coupled with the dedication and experience we fabricate the best air cooler to meet engine demands.

Specialist Services

Our team of dedicated service engineers and designers travel to any part of the world to troubleshoot, repair & replace main engine charged air cooler for any kind of vessels around the globe to the convenience and satisfaction of the client.